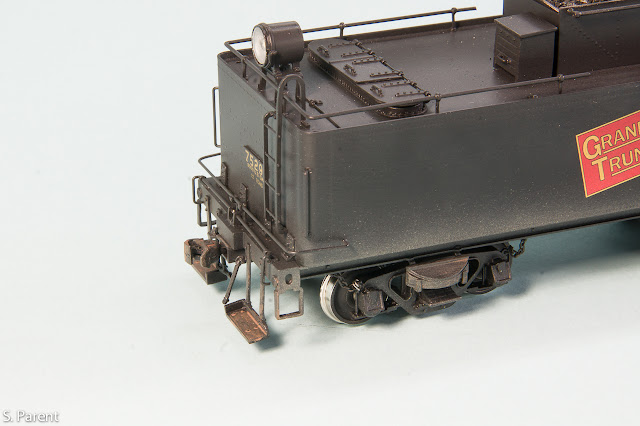

I have completed my customization of the RR model. Here is the final result and a quick explanation of the modifications I did.

One of the difference from the RR model and specifically to road number 7529. Engine 7529 had no safety panels behind the foot board. I wasn't planning on taking them out because I thought they were cast in. After a close examination, I noticed they were add-on and decided to unsolder them. Since I was going to repaint the pilot, I then decided to add the missing poling pockets and improved the look of the coupler pocket using styrene tubing and pieces.

Another small detail that was missing is the electrical box on the front cab wall. I used one of my own castings and fix it with ACC.

Now back to my original plans:

Wipers for Electrical pick-up and the Cam on the Locomotive:

I

replaced the 3 small bearing cover plates on the left (insulated side) with a

long piece of 1/32” double sided PC board. On the side up (bearing

side), I solder a 0.018” thick piece to match the cover plate. On the

down side (towards the tracks), I have first drilled the holes for the mounting

screws and made insulation cuts in the copper to insulate the mounting

screws. Then I made the wipers from 0.005”phosphor bronze flat sheet and solder in

place. I have solder and run a small piece of wire to connect all

three wipers up to the decoder on top of the motor.

For

the cam wiper, I used the brake rigs details as holder. Again, using

the 1/32” double sided PC board, I solder on side on the brake rig, behind the

cam and solder a piece of phosphor bronze on the other side.

Decoder

installation:

At

first, I was going to install the Tsunami decoder (TSU-1000) in the tender.

After test fitting, I realized that I could fit it on top of the motor in

the boiler. Installing the decoder inside the locomotive is my favorite

option for many reasons, for one, less wires between the locomotive and the

tender, especially if you use the mechanical cam trigger and able to fit the

speaker inside the boiler, since I also build or modify all my locomotives for all

wheel pick up, it allows the engine to run by itself without the tender

attached. Not that I run my locomotives without a tender but it makes it

easier during programming or test run. Another advantage as well is to

have as much as possible the wiring on the frame/mechanism and have connectors

for the lights and speaker when taking off the boiler.

Boiler Modification:

I

made 2 minor modifications on the boiler assembly. The first one was to

allow a close coupling of the tender and make an opening below the cab floor to

run the wire harness. To do this, I have unsolder the bumper

casting. This is not a detail than can be seen and additionally, it was

oversize, probably to fill the larger than scale opening between the tender and

locomotive. Then using a cut off tool and some filling, I made an opening

between the 2 screw holes, large enough so that a bundle of several wires can

go through.

I

made 2 minor modifications on the boiler assembly. The first one was to

allow a close coupling of the tender and make an opening below the cab floor to

run the wire harness. To do this, I have unsolder the bumper

casting. This is not a detail than can be seen and additionally, it was

oversize, probably to fill the larger than scale opening between the tender and

locomotive. Then using a cut off tool and some filling, I made an opening

between the 2 screw holes, large enough so that a bundle of several wires can

go through.

The

second one was to open up for about 3/8” longer the wide opening of the

boiler. This was require to be capable of fitting the boiler on top of

the frame with the Tsunami decoder wrapped on top of the motor. Again,

this is not a visible modification, the larger opening remains behind boiler

mounted details.

Speaker

installation:

The

speaker with enclosure is mounted loose inside the smoke box section of

the boiler, replacing the weight. Before doing this, I tested the pulling

power of the locomotive without the weight. It could still pull a 12-car string

of full length AM Pullman cars. That’s good enough for me….. The

speaker must be installed after the boiler is assembled over the chassis,

through the smoke box front.

Here is the smoke box front where I replaced the number board with the correct CN style.

Tender modification:

Then

I have added the wipers on the insulated wheels. That was not an easy job

because the retaining chain details had to be detached and it was not easy to

put them back in place. I have installed the wiper by using my own

etch wiper holders and phosphor bronze wire. I used the existing mounting

screw mount of the truck assembly but replaced with a nylon screw for

insulation. I forgot to take a picture of that before putting back the

truck in place and will not take them out again because of the tedious chain

installation.

Then

I have added the wipers on the insulated wheels. That was not an easy job

because the retaining chain details had to be detached and it was not easy to

put them back in place. I have installed the wiper by using my own

etch wiper holders and phosphor bronze wire. I used the existing mounting

screw mount of the truck assembly but replaced with a nylon screw for

insulation. I forgot to take a picture of that before putting back the

truck in place and will not take them out again because of the tedious chain

installation.

I

have oversee one thing though, I did not revert the insulated side on the

tender. This means that the tender and boiler are not the same

polarity. This is not an issue so to speak but with a close coupling,

there is always a risk of having the locomotive and tender touching in sharp

curves and it might create a short. It is not a problem on my home

layout but it could on someone else or sharp sidings the workshop

modules. If I see that it become a problem, I will make the change but it

means disconnecting the chains again L

Below are additional photos of the finished model.

Nice work, Simon.

ReplyDeleteWhat size speaker did you fit?

KR,

Simon